Building physics basics

Contents:

2. driving rain load

3. temperature differences

4. sound insulation

5. movements from the building

and the window construction

6. air permeability

7. room humidity and ventilation

8. fire behaviour

9. environmental compatibility

10. thermal insulation

11. Building material - Compatibility

1. UV stability

This is defined by the proportion of short-wave rays in the UV spectrum that cannot be perceived by the human eye.

sunlight, which are described as UV rays (ultraviolet).

This radiation exposure damages not only the human skin, but also the skin on the outside of buildings.

sealing materials used on the outside of buildings.

These influences and their effects are repeatedly the subject of controversial discussions.

This is particularly because there are a wide variety of measurement methods for simulating these influences at time-lapse speed.

The test methods used in the paint industry or other surface coatings, for example, have proven to be

proved to be unrepresentative.

Due to economic constraints, sealing products that are not weather-resistant are still being used.

processed. As a rule, these lead to the failure of the sealing system within a very short time.

2. driving rain load

External component joints are subject to natural exposure to driving rain. Here

raindrops are pressed against external wall components by wind pressure (up to 600 Pa corresponds to approx. 12 Beaufort) or as a result of air currents,

pressed against exterior wall components. The penetration of this moisture must be prevented, either structurally or by using suitable sealing products.

Absorbent or capillary-forming joints in the building connection represent a further moisture load.

The capillary action (narrow joint) draws water into the building structure without the effect of wind pressure.

In the external area of the building envelope,

1. ensure a defined drainage of moisture from the structure.

2. the uncontrolled ingress of water into the structure must be prevented.

3. limit the moisture content of sensitive materials.

4. a defined removal of moisture from the construction must be ensured.

| Materials of the window profiles | ε in mm/m |

| PVC hard (white) | 1,6 |

| PVC hard (coloured) and PMMA coloured extruded | 2,4 |

| Thermally insulated aluminium composite profile (light) | 1,3 |

| Thermally insulated aluminium composite profile (dark) | 1,2 |

3. temperature differences

Thermally induced movements occur in practically every joint. With timber frame material, however, the thermal movements are so small compared to the moisture-related movements that they

can be

neglected

.

With dark-coloured façade components made of aluminium or plastic, surface temperatures of over 80 °C occur on the south side. Depending on the material composition and changes in length, this results in movements of

up to 3 mm per running metre. For this reason, the

temperature changes in the profiles caused

by the outside climate that occur during installation are

decisive. These movements must

be absorbedby the

sealing materials

used

.Taking into account research results on the actual length movements that occur

the following temperature-related changes in the connection joint can be assumed:

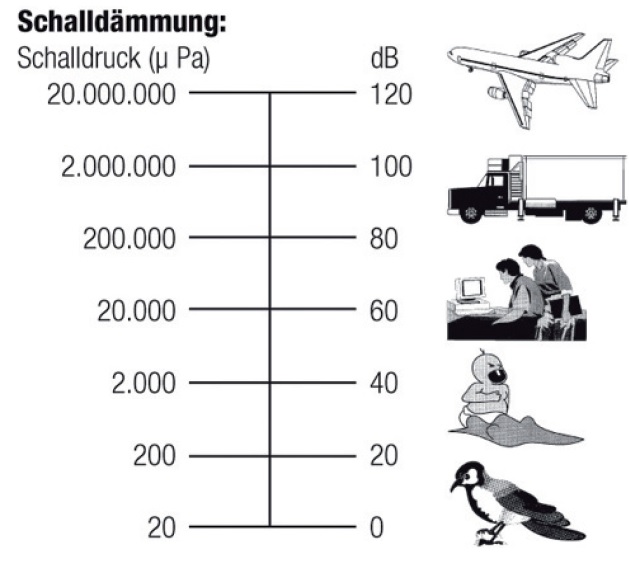

4. sound insulation

The so-called keyhole effect is particularly important in this context. Small openings or hairline joints

in the connection area can have a negative effect on the sound insulation values.

The human ear perceives

a reduction of the sound level by 10 dB

as a halving of the volume.

An unfilled joint has a sound insulation value of 15 dB. A mineral wool plait achieves approx. 35 dB, and

a joint filled with sealant achieves the same value. A compressed sealing tape achieves sound insulation values

greater than 42 dB.

There are two sets of regulations for the sound insulation requirements of windows, which contain the recognised rules

of technology. In addition to DIN 4109 "Sound insulation in building construction", which has been introduced by the building authorities,

the VDI guideline 2719 "Sound insulation in building construction and its additional equipment"

is alsofrequently referred to

.5. movements from the building and the window construction

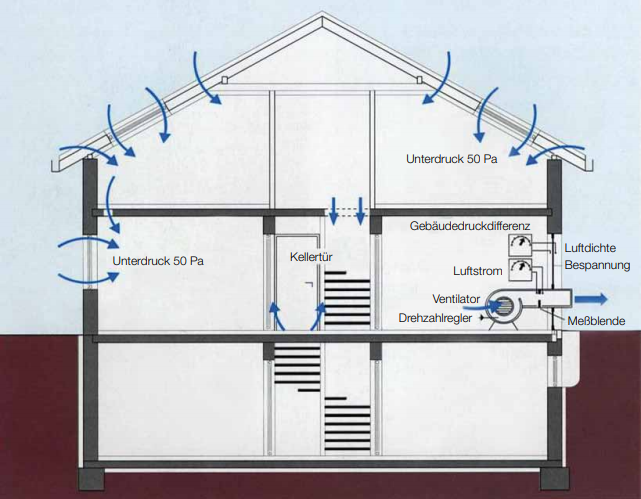

Principle of measuring air permeability. When windows and doors are closed, the speed of the fan is increased until a building pressure difference of building pressure difference of 50 Pa, for example. The volume flow to be read is referred to as the volumetric flow of air permeability .

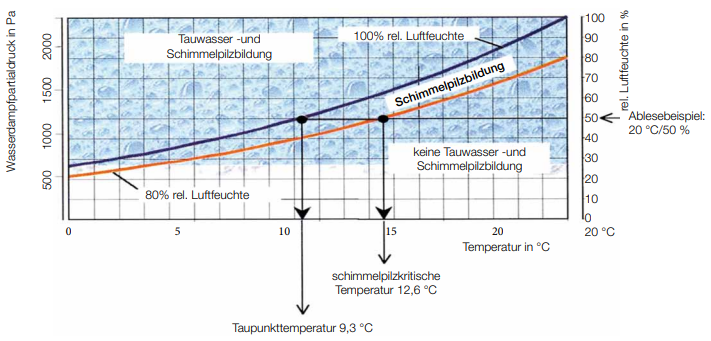

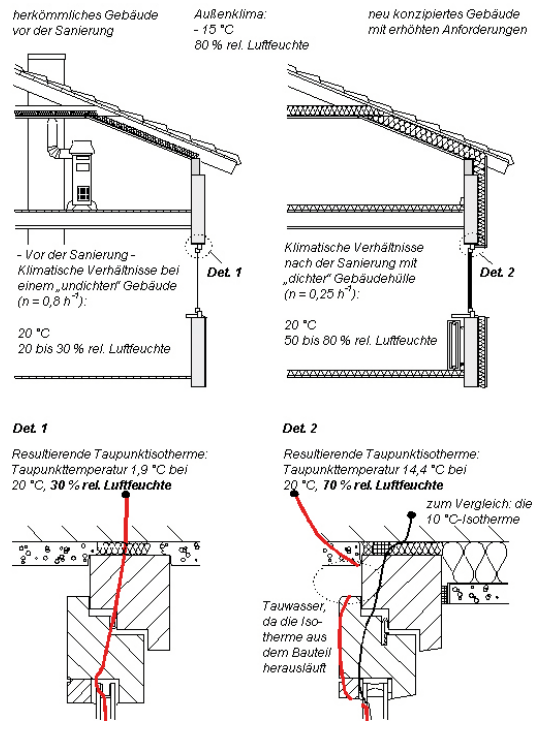

7 Room humidity and ventilation

If, as mentioned in Chapter 6, the component temperature drops and the ambient air is no longer able to absorb the moisture, condensation will occur. A temperature of 12.6 ºC has proven to be critical in this case. Using special software, the surface temperatures are determined in a building connection and connected to form a line, the so-called isothermal curve.

In the past, this was commonly referred to as the 12 ºC isotherm. More precise scientific investigations have now led to the aforementioned 12.6 ºC. In popular science, the 13 ºC isotherm has been agreed upon.

8 Fire behaviour

According to the requirements of the state building regulations, the building materials used and thus also the materials used for the connection design must fulfil at least building material class B 2 according to DIN 4102 or the corresponding class E according to EN 13501-1. class E according to EN 13501-1.

9. environmental compatibility

In general, there has been a general shift towards environmentally friendly products in building construction and civil engineering in recent years. environmentally friendly products. The use of products containing solvents, for example , has fallen sharply. Only in areas where these cannot be replaced are they still used at all .

Products whose process is based on a chemical function are also used to a lesser extent. Pre-compressed sealing tapes in particular have an advantage here, because their application is based on physical processes. physical processes.

Furthermore, sealing products make a significant contribution to positively influencing the indoor climate and thus significantly

improving the energy efficiency of a building. The energy efficiency of a building is significantly improved , thus contributing to a further reduction in global environmental pollution.

10. thermal insulation

When sealing windows and external doors, thermal insulation is a physical property of the building, the consideration of whichis also required by the legislator through regulations and ordinances introduced under building law .

In this context, the Energy Saving Ordinance (EnEV) and DIN 4108 "Thermal insulation and energy saving in buildings" are of particular importance.

Thermal insulation in new buildings

In

newly constructed buildings, a type of construction that is as free of thermal bridges as possible should be selected.

This essentially consists of three requirements in the window connection:

- Insulation elements should be joined without gaps

- The sealing materials should have the highest possible thermal resistance.

-The construction must be selected in such a way that the maximum possible amount of sealing or insulating elements can be accommodated.

Thermal insulation in old buildings

In general, the same standards apply for renovation as for new buildings. However, these can only be realised very rarely in practice , as you have to rely on the existing framework conditions.

For this reason, cover strips fitted with sealing tapes are very often used. Such solutions are certainly not ideal in terms of thermal insulation, but in many cases they are the only solution.

11. building material compatibility

In many cases, the sealing of joints represents a link between different materials. These can be paints, treated timber constructions, various plasters or even residues from existing sealing products.

To ensure that the sealing product can fulfil its requirements in the long term, no harmful interactions may occur. These can be chemical, physical or even visual impairments , which must generally be avoided. Compatibility tests must be carried out to ensure this.

As a rule, pre-compressed sealing tapes have an advantage here, as only physical expansion takes place.

Depending on the installation position of the window, the materials listed below can lead to impairment of the sealing products:

- the paint system of the façade or window

- Impregnation systems of a timber construction

- Old sealing materials

- Release agents from the production of window profiles

- Natural pests

12. assembly on site

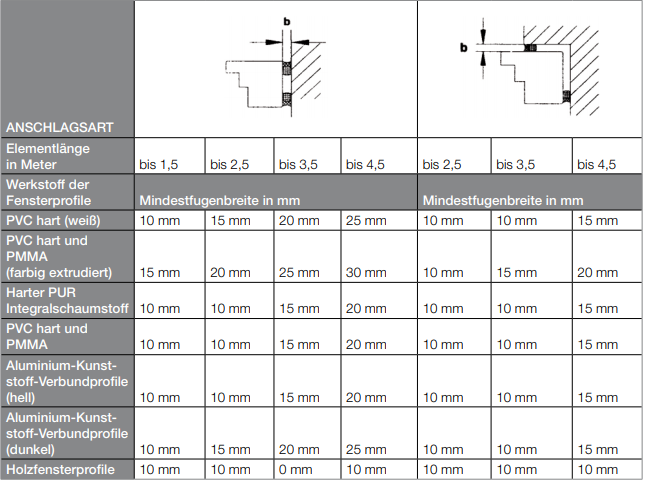

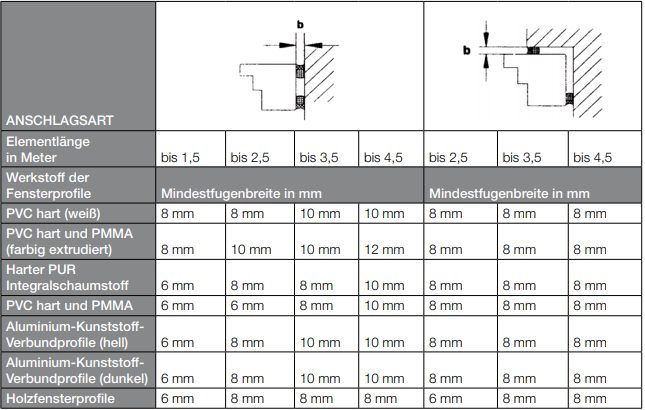

The dimensions for dimensioning with sealants are shown here.

The significantly wider joint widths can be seen very clearly in the table.

12. construction site installation

To ensure that as few errors as possible are made when dimensioning pre-compressed sealing tapes , the table below has been drawn up by ift Rosenheim . A comparison of Table 1 with Table 2 quickly shows that the joint can be made narrower when using sealing tapes than when using pasty sealants. This is a clear economic advantage of sealing tapes.

Joint sealing of exterior wall components

The problem of sealing is probably as old as man's desire to influence his environment to his advantage and benefit,

to influence his environment to his advantage and benefit. Even in the animal world, activities with the purpose of sealing can be recognised. For example: bees usea wax (propolis) they produce themselves specifically for this purpose to seal their hive against draughts and rain.

Some birds also seal their brood cavities against external influences, using natural aids such as salivated soil, debris and parts of plants. There isno significant differencebetween the aforementioned natural sealants and the sealing of external joints, neitherin terms of the task to be performed nor the desired effect. In both cases cited , the aim is to protect an area from the effects of the weather. Essentially from wind, moisture and heat loss.

_400x400.webp?ts=1735165250)